Everyone always stresses recycling e-waste, but we often see the numbers not adding up. According to an estimate by The Swedish Commission Agency, 2-11% of Li-ion batteries end up for EV battery recycling after they die. By comparison, the Li-ion production industry can boom exponentially (up to 800 GWHs) in the next three years.

When we look at such statistics, we often hear recycling companies and activists questioning the future of recycling and how important it is to bring about the green revolution. While everyone is doing what they can in their domains, Recycle Technologies, a minority-owned Midwestern recycling company, is trying to answer the hard-hitting recycling questions.

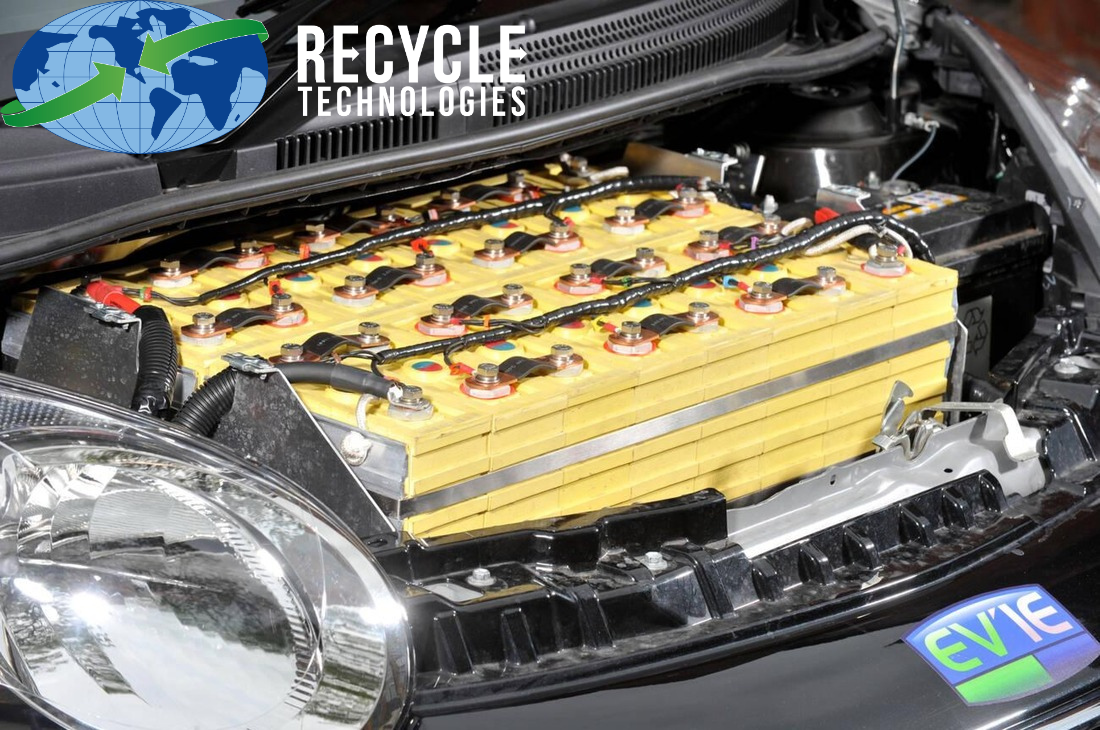

Our professionals always caution against the freeway disposal of e-waste, especially batteries, which can leak toxic chemicals. In this blog, we highlight how EV battery recycling is handled at our facilities, bridging the gap between consumers and service, and how the importance of battery recycling will improve in the future.

How Does Recycle Technologies Handle EV Batteries?

On average, most electric car batteries are built to last around 10-15 years (150-200k miles). Once they hit those ranges, the battery typically runs out of capacity and can no longer work. Additionally, electric vehicles started springing up a decade ago, so we can now see people questioning us about EV battery recycling.

A quick Google search of "recycle battery near me" and you will find Recycle Technologies recycle centers within a 100-mile radius . Our localised special facilities in Minnesota and Wisconsin are fully equipped to break down the batteries for the valuable metals inside.

The batteries are disassembled by shredding, separating the different components by size and material for further processing. Ferrous and nonferrous metals are separated from materials like plastics. Many metals in these batteries are extracted, such as cobalt, which can be reused indefinitely once purified. We remove these metals using pyrometallurgical and hydrometallurgical processes.

Recycle Technologies hopes to see breakthroughs in more efficient ways to manage lithium-ion batteries over the next decade.

Current Challenges with EV Battery Recycling

The following are some of the prominent challenges facing recyclers worldwide.

Logistical Challenges

One big challenge in recycling electric vehicle (EV) batteries is that so many of them are coming onto the market. As more people buy electric cars, more batteries reach the end of their life. Dealing with this substantial number of batteries is a logistical problem involving collecting, transporting, and processing them.

On the other hand, some recyclers say they do not have enough batteries to recycle. But as electric cars become more popular and affordable, more people will own them. Either way, we need a sound system for collecting and recycling these batteries. This way, we can make sure everyone understands how important it is to recycle EV batteries.

Complexity of EV Battery Recycling

Electric vehicle (EV) batteries blend diverse materials, encompassing metals such as lithium, cobalt, nickel, and manganese. It is imperative to separate and handle these materials to achieve optimal recovery and reduce environmental repercussions. Nevertheless, the elaborate procedures needed for this separation and treatment can prove time-consuming, resource-demanding, and financially burdensome.

Absence of Standardisation

The need for standardisation in battery designs and chemistry further complicates the recycling process. No two Li-ion cells of an EV battery are the same. Different manufacturers often use other materials and configurations, which makes it challenging to develop a streamlined recycling infrastructure. It is a straightforward logic: a Tesla SUV or truck cannot run on the same type of battery that runs Tesla cars.

The lack of standardisation increases costs and hampers the scalability of recycling operations globally. For better or worse, it is not a by-product of organisational politics, just today's technological limits.

Future of EV Battery Recycling

For the future, improving the current electric vehicle (EV) battery recycling process is crucial for sustainability and reducing environmental impact. As a leading recycler dealing with EV batteries, we feel like these are some of the steps that can enhance the EV batteries recycling process:

Process Efficiency Innovation

The complete recycling process for EV batteries needs efficient innovation from collection to separation. There have been steps to automate the separation process, purging plastic and other waste quickly with the help of robotics. However, it can prove to be expensive for smaller recyclers.

For such businesses, it is essential to focus on other aspects of the recycling process and work on speeding up the work that way.

Regulation

Even now, many governmental regulatory bodies still need concrete plans for curbing electric car battery waste. We need to implement and update regulations that support responsible battery recycling, including requirements for manufacturers to take responsibility for the end-of-life phase of their products.

Consumer Awareness

We must educate consumers about the dangers of improper battery recycling. One way to make the public aware Is if regional recyclers conduct symposiums where consumers can directly engage with the recycling processes.

Economic Incentives

If not for human health or the environment, then for the economy. As sad as it sounds, the more electric vehicle batteries are recycled, the more the demand for renewed ones will increase. We need the market to flourish for the incentives to roll in for everyone involved.

When implemented comprehensively, these steps can significantly improve the current electronic vehicle battery recycling process, making it more efficient, environmentally friendly, and economically viable.

Conclusion

While there are ongoing efforts to address these challenges, the current limitations in EV battery recycling underscore the need for continuous innovation and collaboration across industries. Governments, manufacturers, and recycling facilities must work together to establish standardized processes, invest in research and development for more efficient recycling technologies, and create incentives for proper battery disposal and recycling.

Overcoming these challenges and limitations is crucial for Recycle Technologies to ensure a sustainable future for electric vehicles and clean energy. By revolutionising the recycling processes and establishing a robust infrastructure, we can maximise the value of spent EV batteries, minimise waste, reduce reliance on raw materials, and pave the way for a truly circular economy in the clean energy sector.

Want an EV battery to recycle? Head on to our website for more information.